Why Aluminum Roller Design at Cbbmachine Reflects Modern Efficiency

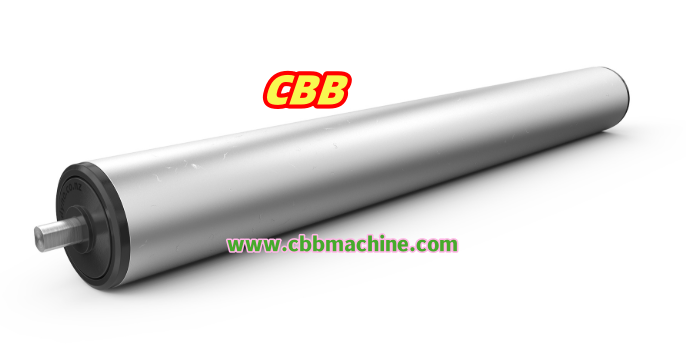

In the expanding field of industrial motion systems, the Aluminum Roller created by Cbbmachine demonstrates how subtle engineering choices influence consistency and flow. It is not defined by shine or surface alone but by the balance between strength, weight, and form. This component, often overlooked in the complexity of production lines, becomes essential when every rotation carries both pressure and purpose.

Its lightweight frame allows for smoother transitions across conveyor paths and reduces mechanical strain during continuous operation. The internal geometry aligns movement with intent, allowing materials to advance with reduced resistance and predictable rhythm. Each section of the roller contributes to a quiet continuity where energy is conserved through balance rather than force.

Beyond movement, the design speaks to durability achieved through restraint. By limiting unnecessary density, the roller avoids excess friction while maintaining alignment under load. The choice of aluminum is not a matter of trend but of understanding: that lasting performance often comes from measured simplicity. When tension and rotation coexist without conflict, the result is precision that can be felt in every stage of production.

This measured design approach reveals an underlying philosophy. It values stability without excess, clarity without ornament, and longevity without dependence on complex maintenance. Such qualities make the component adaptable across diverse industries, from packaging to processing, wherever controlled motion defines productivity. The roller's character lies not in its presence but in its seamless participation within the system—its ability to disappear into efficiency.

In daily operation, small shifts in design translate into noticeable gains. Surfaces stay clean, motion remains even, and alignment endures through continuous cycles. Operators sense less vibration, and systems experience fewer interruptions. It is not about speed alone but about maintaining rhythm—a partnership between structure and motion that respects both function and time.

Precision, in this sense, becomes a quiet dialogue between material and purpose. The roller embodies that dialogue, turning repetition into reliability and movement into method. Each rotation is an affirmation that subtle design choices can carry significant influence when executed with intention.

If you find purpose in the balance between material and motion, allow curiosity to guide your next step. The story continues beyond this page—follow its quiet rotation at https://www.cbbmachine.com/news/industry-news/aluminum-roller-vs-pvc-roller-which-one-is-better.html and see where the movement leads.